Solutions

Scanning Acoustic Microscope

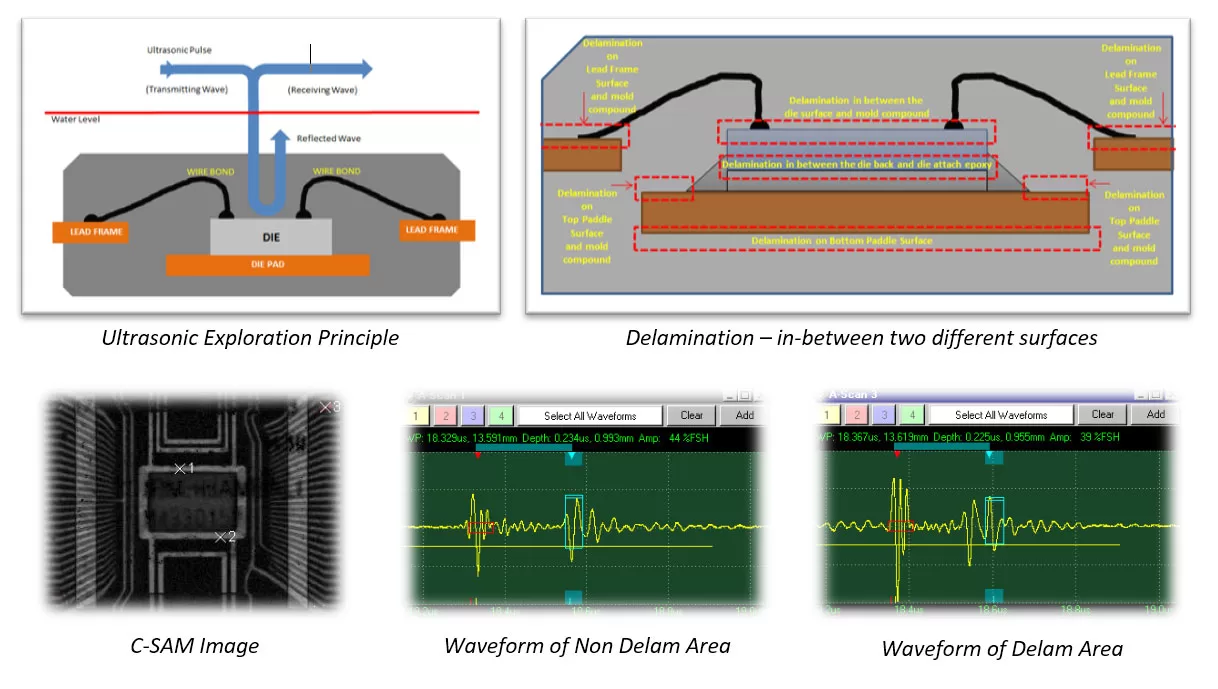

Scanning Acoustic Microscopy [SAM] is a failure analysis used to detect delamination or disbands between the package interfaices. For example, interfaces between the die and plastic compound, between the leadframe and compound. Etc [Refer Illustration diagram below for more details].

It basically consists of sending a sound wave through the package, and interpreting the interaction of the sound wave with the package. A typical scanning acoustic microscope may employ either pulse echo or through transmission inspection to scan for disbonds or delaminations. Pulse echo inspection consists of interpreting echos sent back by the package while through transmission inspection consists of interpreting the sound wave at the other end of the package, after it has passed through the latter. The ultrasonic wave frequency used ranges from 5 to 150 MHz.