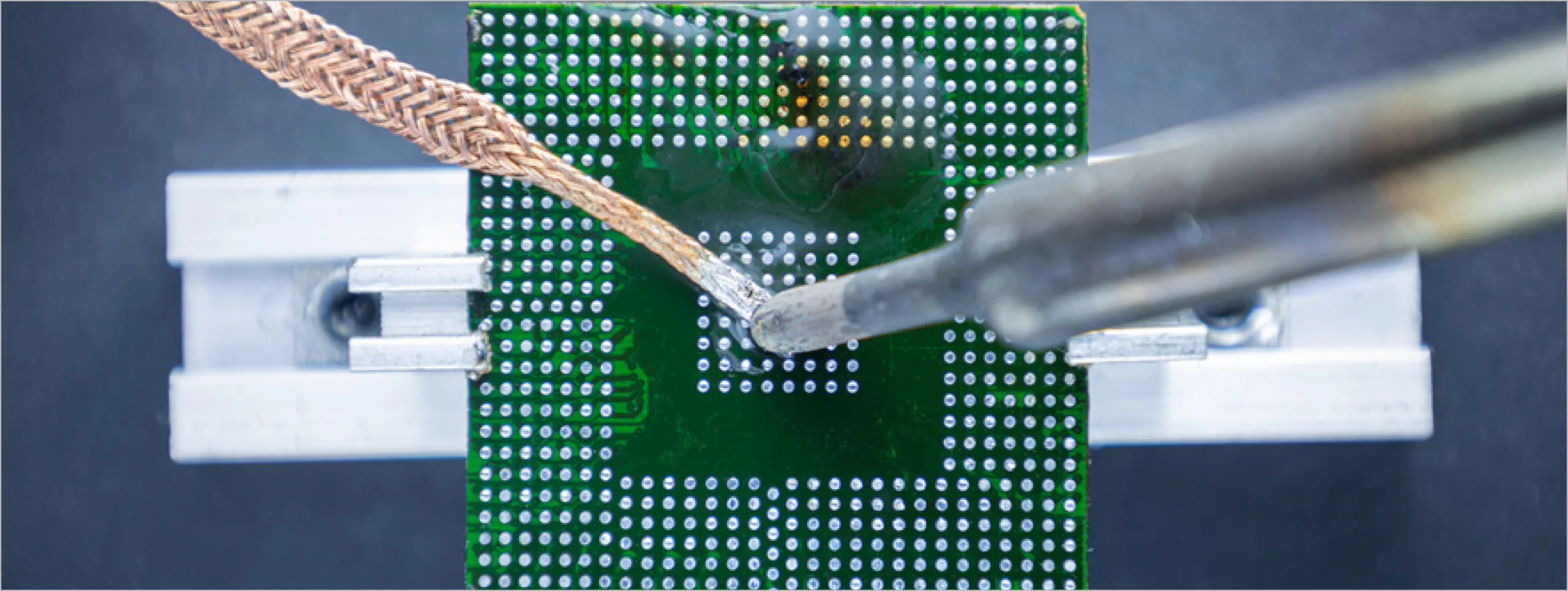

BGA & PCBA Rework / Repair

Ball grid arrays assist in achieving precision and providing additional space on the board for efficient and accurate component mounting. With advancing technology, there is a growing need for PCBs to shrink in size while maintaining consistent results and quality. The precise mounting of components on PCBs is paramount, achievable through either through-hole technology or surface mounting.

Procedure for Re-balling Ball Grid Arrays (BGAs) & Micro BGAsBGA

Step 1:

INCOMING DAMAGED BGA

- Solder ball removal

- Visual Inspection

Step 2:

REMOVE SOLDERS

- Cleaning

- Bake for 2 hours

- Flux printing & Re-balling

Step 3:

AFTER RE-BALLING

- Re-flow process

- QA Inspection

- All tests to follow IPC Standard

PCBA Rework Capability

- Lifted pads

- BGA rework (Removal & Attachment)

- Broken trace (Add / Remove trace)

- Edge damage

- Oxidization treatment (Component & PCB)

- Masking

- Eyelet rework

- Warpage

- Delamination

- Gold plating