Solutions

Thermal Shock Test

Altitude Test

Solderability Test

Adhesion Test

Colour Assessment Test

ESD Analysis (RTG & Walking Test)

Non-Destructive Test

Destructive Test

Supply of Environmental Chamber

Preventive Maintenance Services

Material Sorting Activities

Chamber Repair Services

Visual Inspection

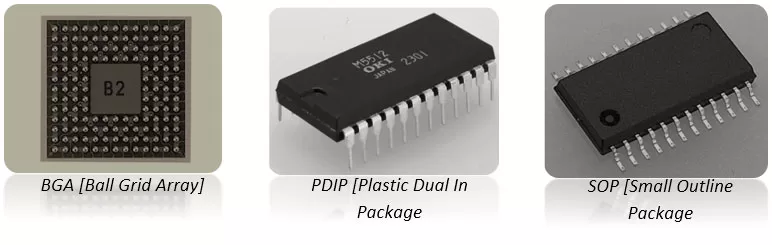

Visual inspection is the process of checking a product’s exterior for defects that might lead to failures, typically focusing on cosmetic issues that could affect functionality. The inspection often follows standards like IPC and JEDEC for ICs, while other products are compared with known good samples. Any abnormalities found are recorded as findings. Most inspections are done under low magnification (5X–60X), but high-powered scopes or SEM may be used for further confirmation. This step is critical, as external defects like lead whiskers causing shorts or corrosion causing electrical failures can significantly impact performance.

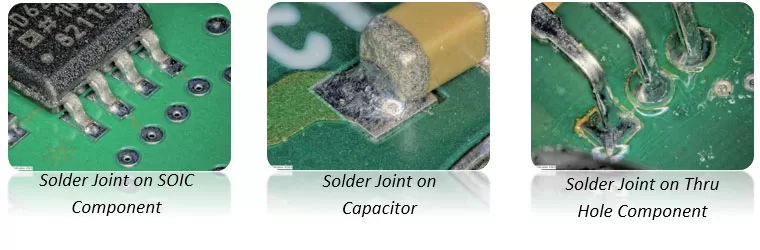

Below are images showing defects observed during solderability inspection on the lead side.